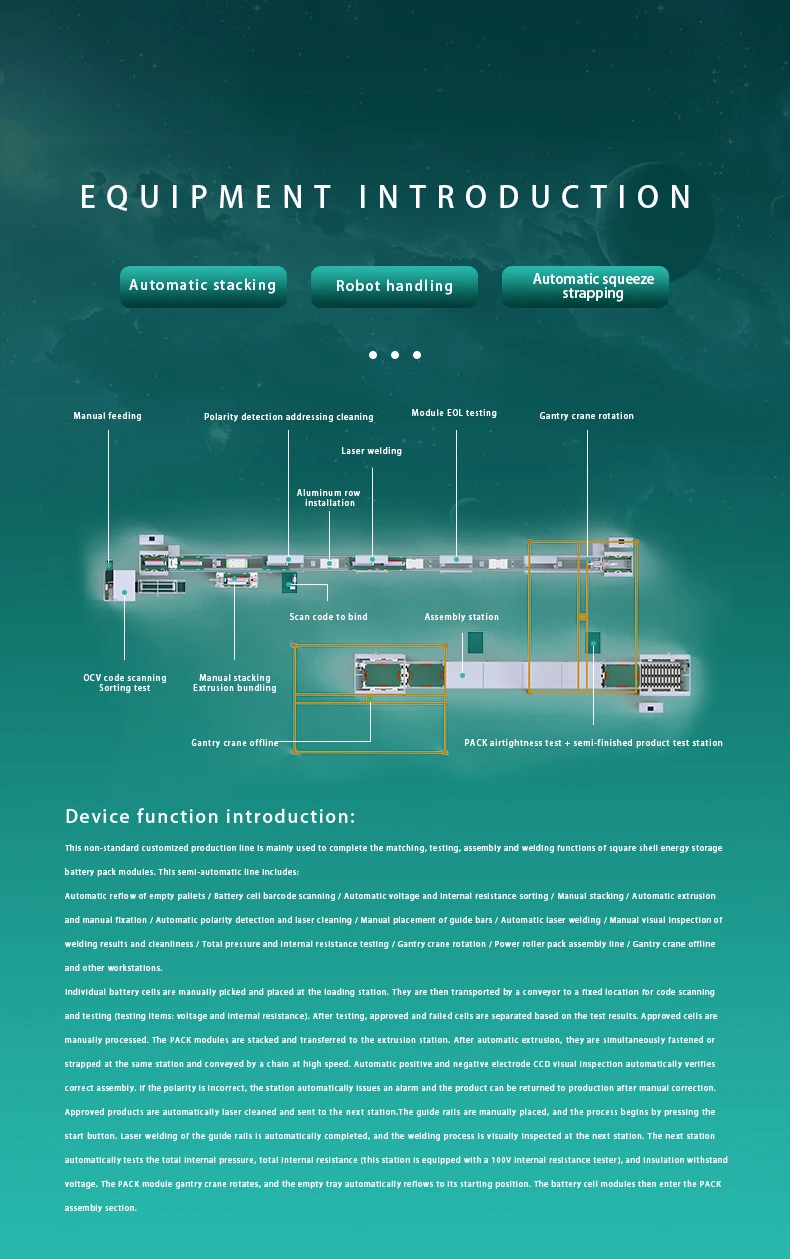

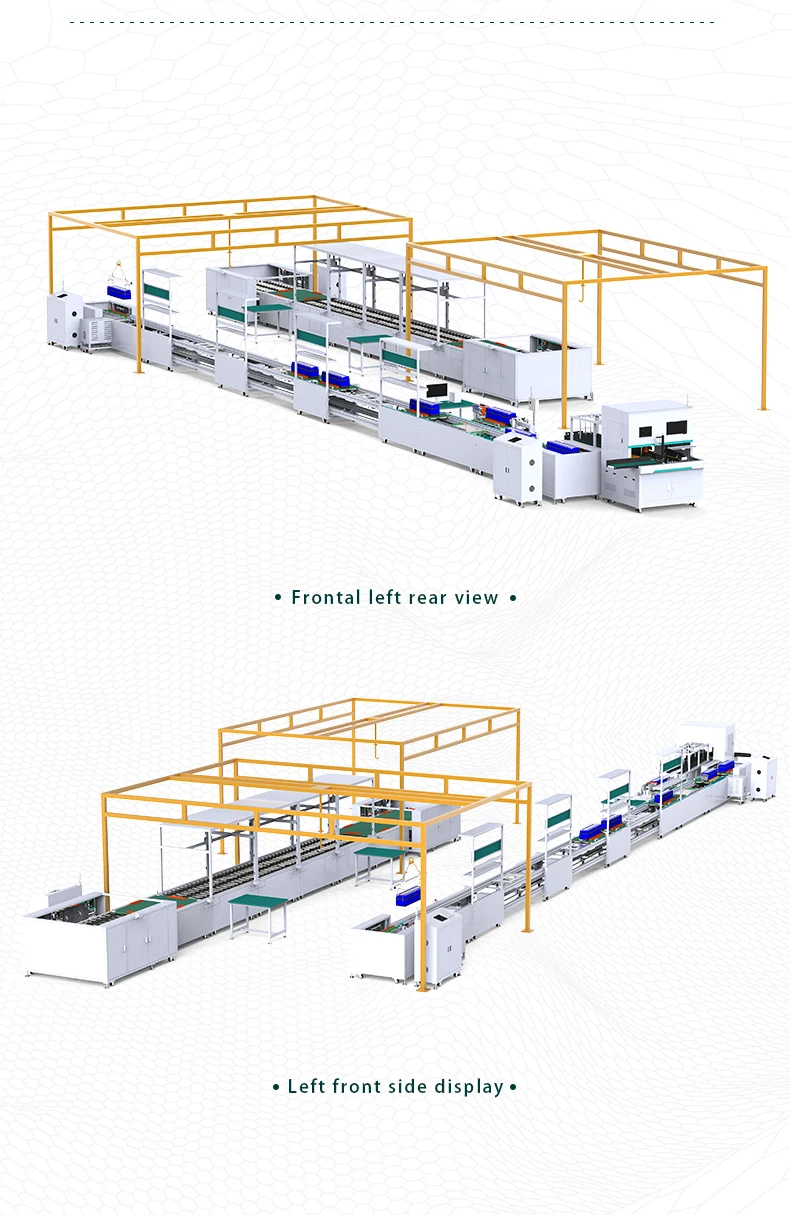

This customized production line primarily performs the assembly, testing, assembly,

and welding of prismatic energy storage cell pack modules. This semi-automatic line includes

automatic empty tray reflow, cell barcode scanning, automatic voltage and internal resistance

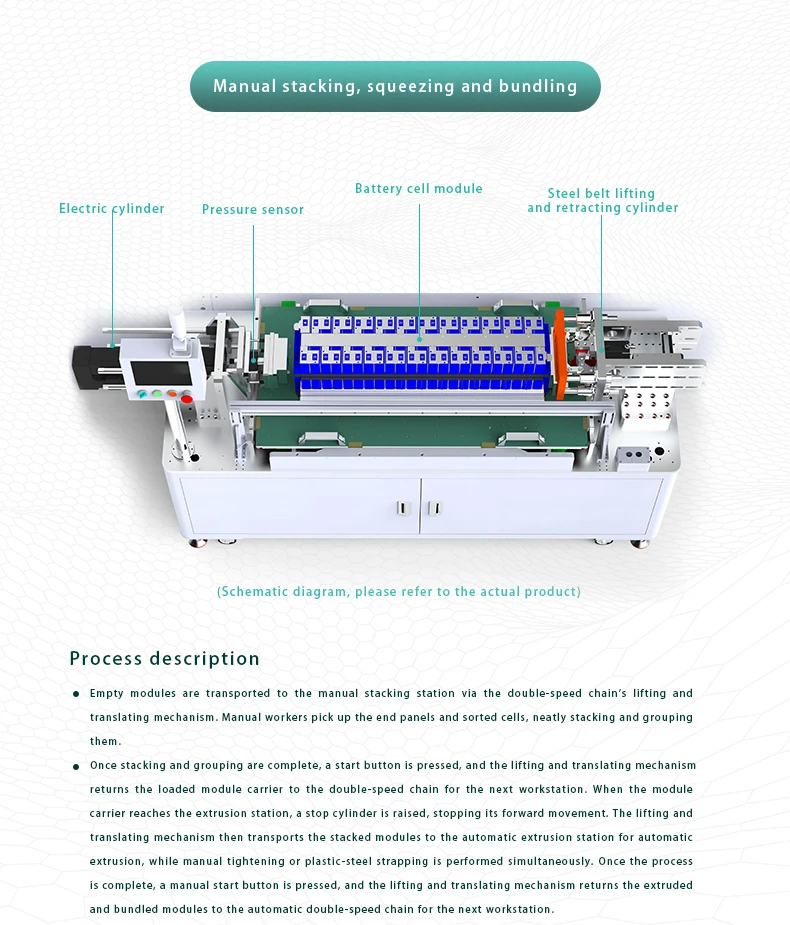

sorting, manual stacking, automatic extrusion and fixation, automatic polarity detection and laser cleaning,

manual guide bar placement, laser welding, manual visual inspection of welding results and cleaning,

total pressure and internal resistance testing, gantry crane rotation, power roller pack assembly, and gantry crane unloading.

Don't hesitate contact us to get more professional battery pack assembly line solutions

We provide the optimal solution based on your budget.

Pls. feel free Contact us for any inquiries or project consultation.

We will provide you with professional solutions tailored to your specific needs.

The following questions will help us move the project forward

Q1, Provide the plant layout drawing in CAD format.

Q2, Provide product 3D models, e.g., modular PACK assembly CAD models

Q3, Provide the production line's cell compatibility specifications and production throughput (takt) parameters.

Q4,Provide the process flowchart of the production procedure

For more professional issues, we need to further confirm

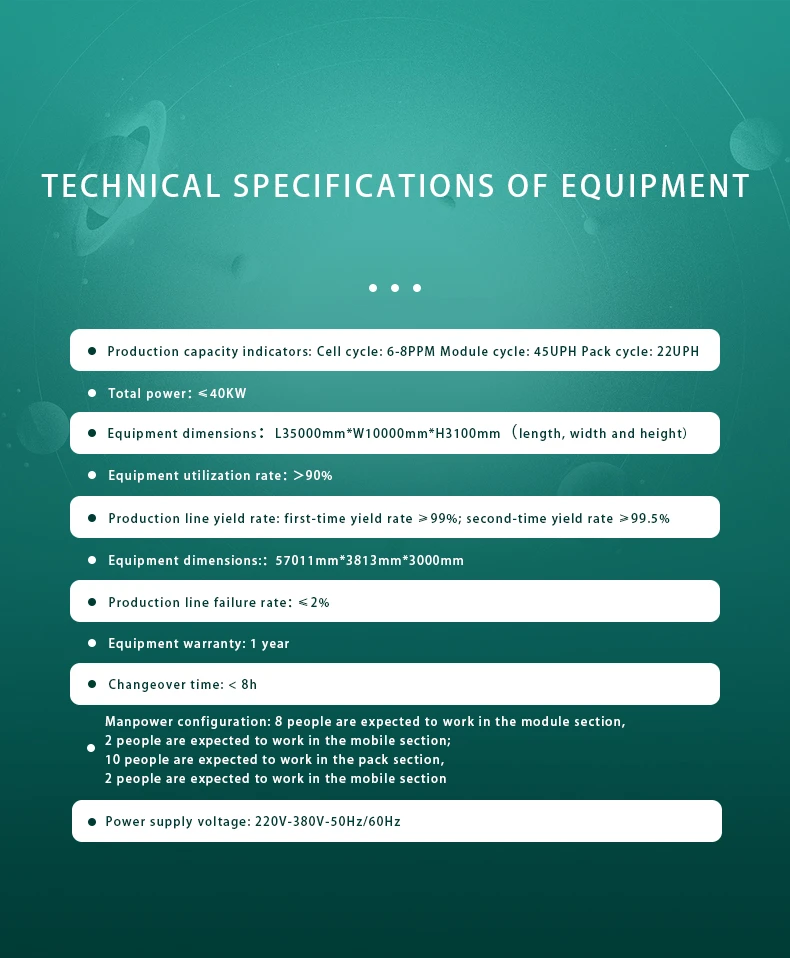

Customized Non-standard Prismatic Lithium Battery Pack Manufacturing Line.