Don't hesitate contact us to get more professional battery pack assembly line solutions

We provide the optimal solution based on your budget.

Pls. feel free Contact us for any inquiries or project consultation.

We will provide you with professional solutions tailored to your specific needs.

The following questions will help us move the project forward

Q1, Provide the plant layout drawing in CAD format.

Q2, Provide product 3D models, e.g., modular PACK assembly CAD models

Q3, Provide the production line's cell compatibility specifications and production throughput (takt) parameters.

Q4,Provide the process flowchart of the production procedure.

For more professional issues, we need to further confirm.

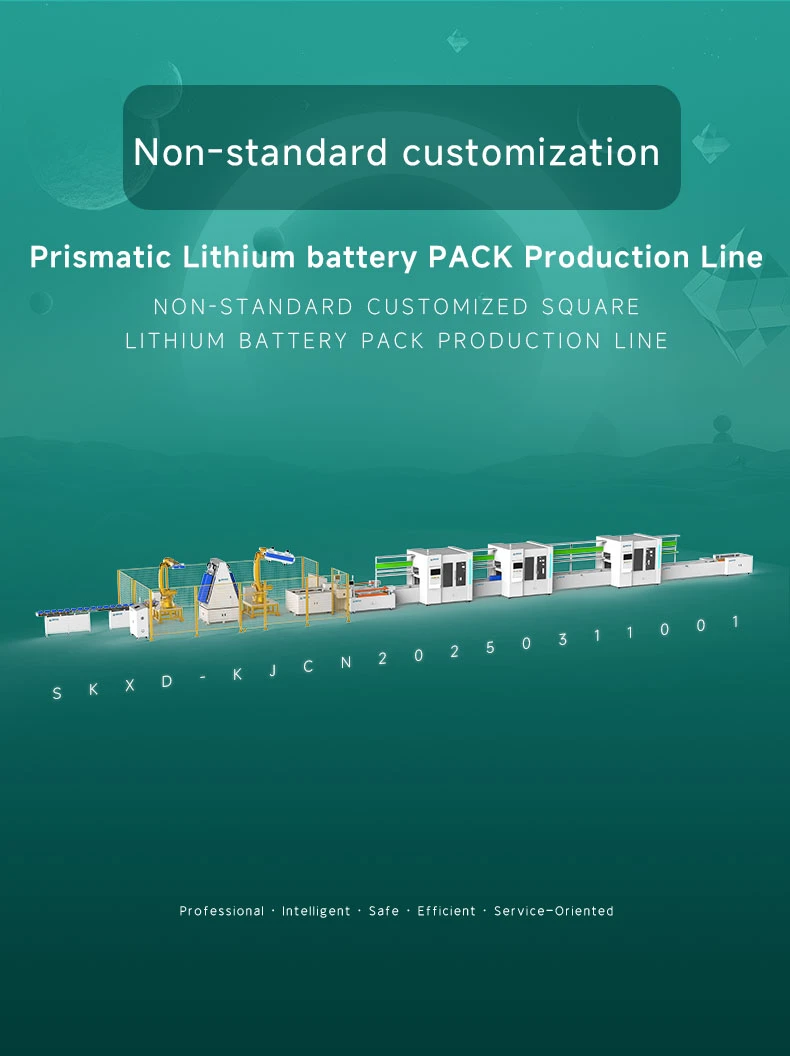

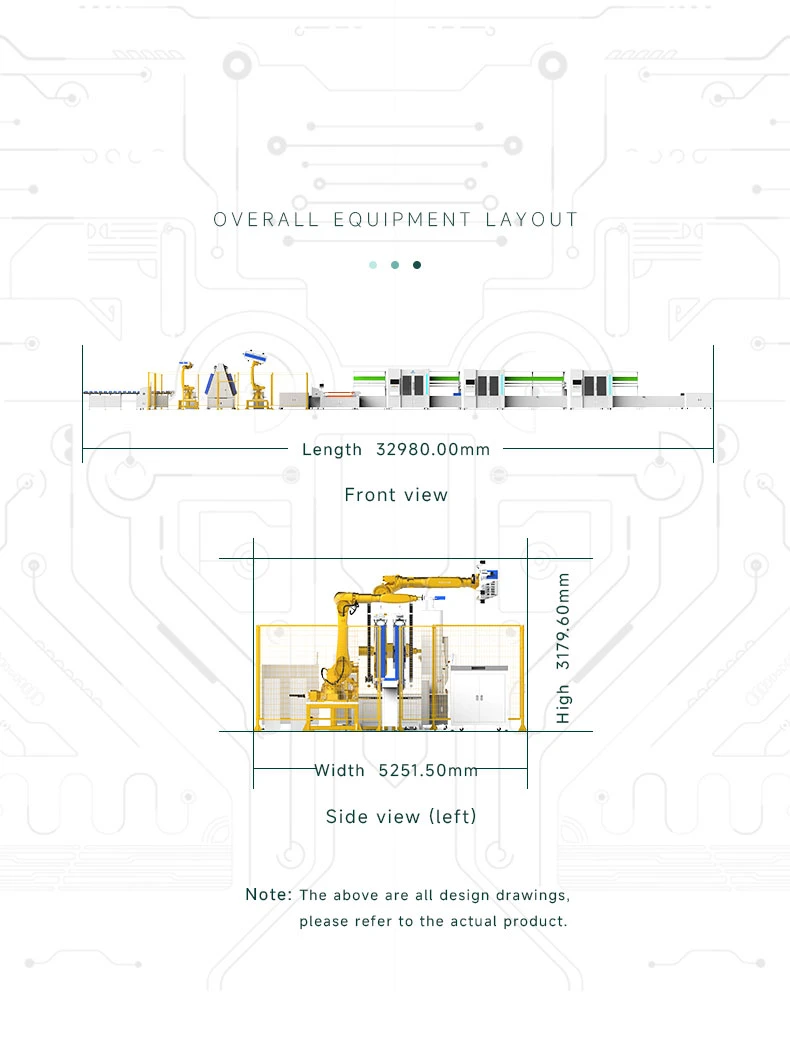

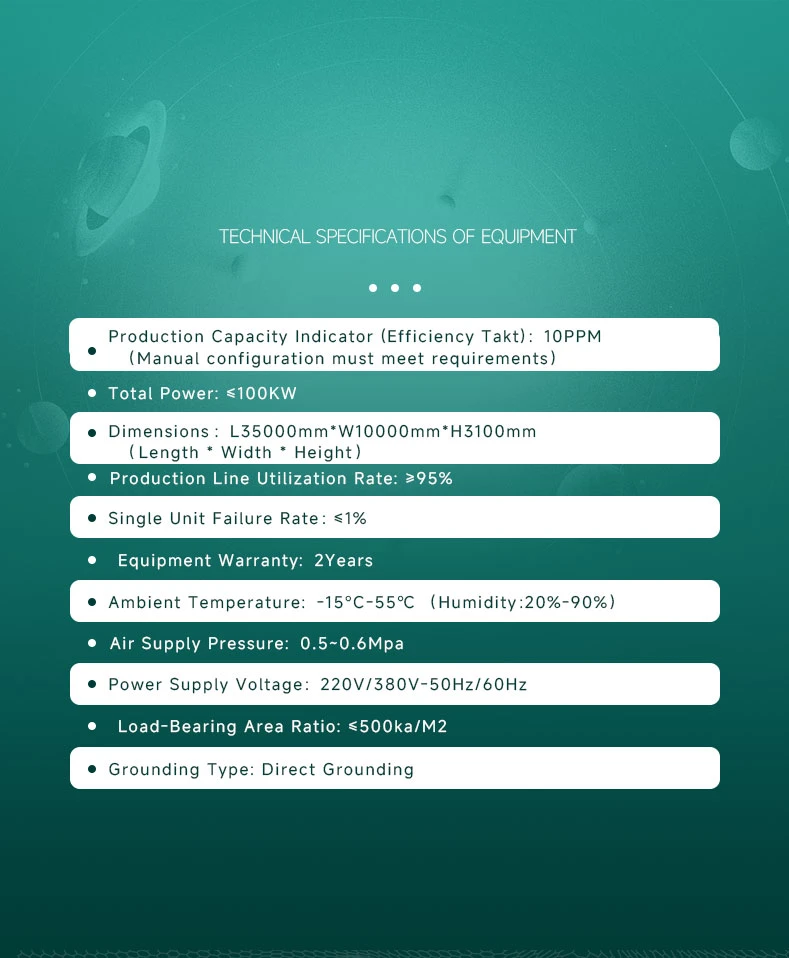

Customized Non-standard Prismatic Lithium Battery Pack Manufacturing Line

Production Line Functions and Requirements

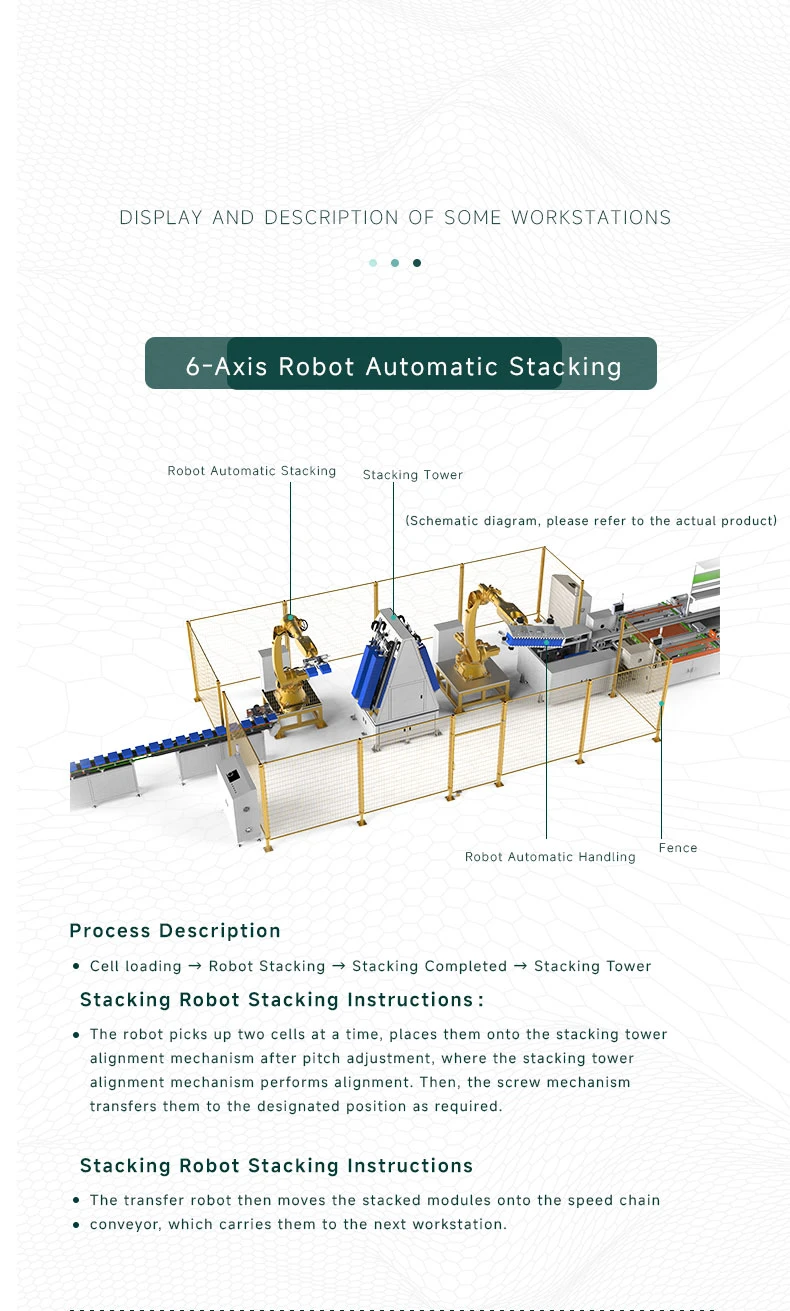

This equipment is designed for the palletizing of prismatic aluminum-shell battery cells

and the automated production of battery cell modules.

Module Section:

The process includes:

* •Robotic module stacking

* •Robotic module handling and transfer to the production line

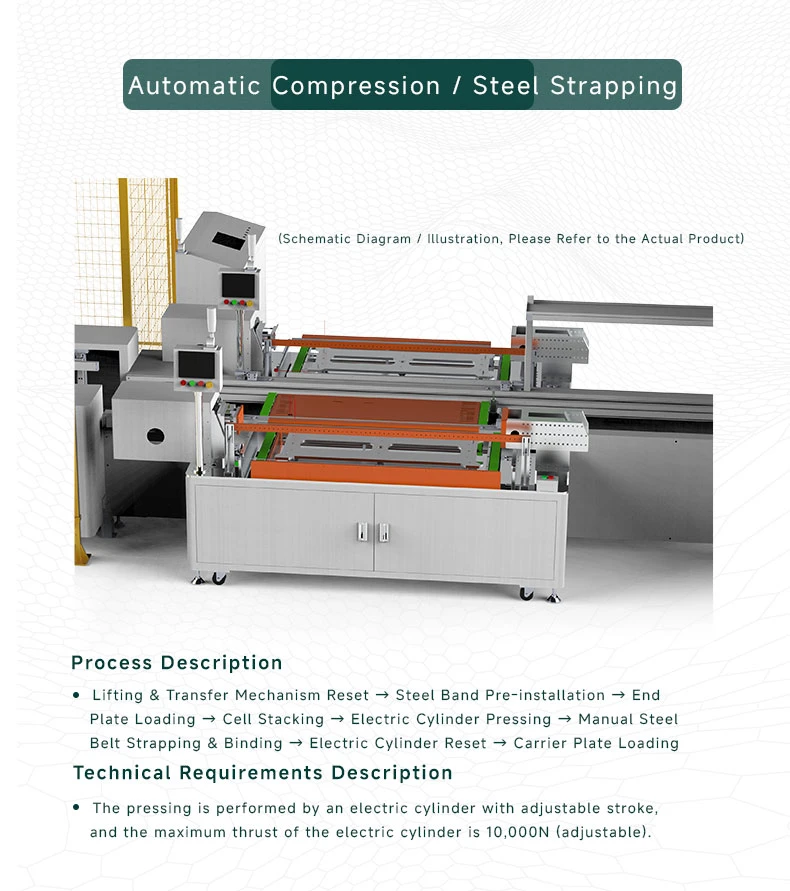

* •Installation of module steel straps and end plates

* •Module polarity testing

* •Terminal post positioning and addressing

* •Module terminal post cleaning

* •Installation of module CCS (Cell Connection System)

* •Laser welding of module CCS

* •Module off-line (unloading)