Flow of Work

1. The artificial future material cell is placed on the assembly line of the sorting machine, which detects the cell OK or NG.

2. The OK cells above the sorter are placed on the loading plate in turn, and the steel strip or molded steel strip is placed

through the stacking extruder.

3. The tooling board is transported to the polarity detection machine through the double speed chain for detection,

and the OK flows to the laser cleaning machine to clean the cell column.

4. Manual work to install the ccs mounting board on the cleaned module.

5. The tooling plate is connected to the laser welding machine through the double speed chain.

After the welding is completed, the welding position is manually detected.

6. After the detection, to the comprehensive test machine, the module for detection.

Equipment specification and parameters

contour size of the unit:Length, width and height: W29072 * L2968 * H2493(Customizable)

Work environment requirements:Temperature 0℃ -50℃, no pollution and strong electromagnetic interference

Gas source requirements:0.5-0.6Mpa

The Main Equipment (Customizable)

1.Stacking extrusion machine

2.The CCD polarity detection machine

3.A 200w laser cleaning machine

4.A 6000W laser welding machine

5.Comprehensive test machine

6.Double speed chain

The following are the relevant machines involved:

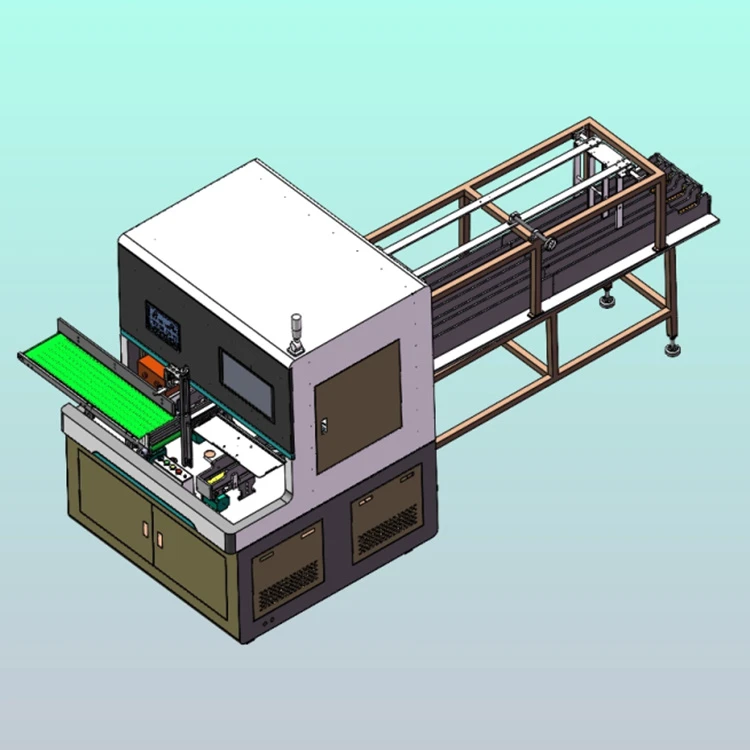

1. Shorting MachineFunction overview: first artificial to put the whole battery on the feeding line, feeding line individually to sweep code binding, then to the test area for data testing, and sweep code data with qr code binding together, after the completion of the test sorting with the manipulator put different voltage batteries into the sorting line,into the corresponding gear bin, so cycle. |

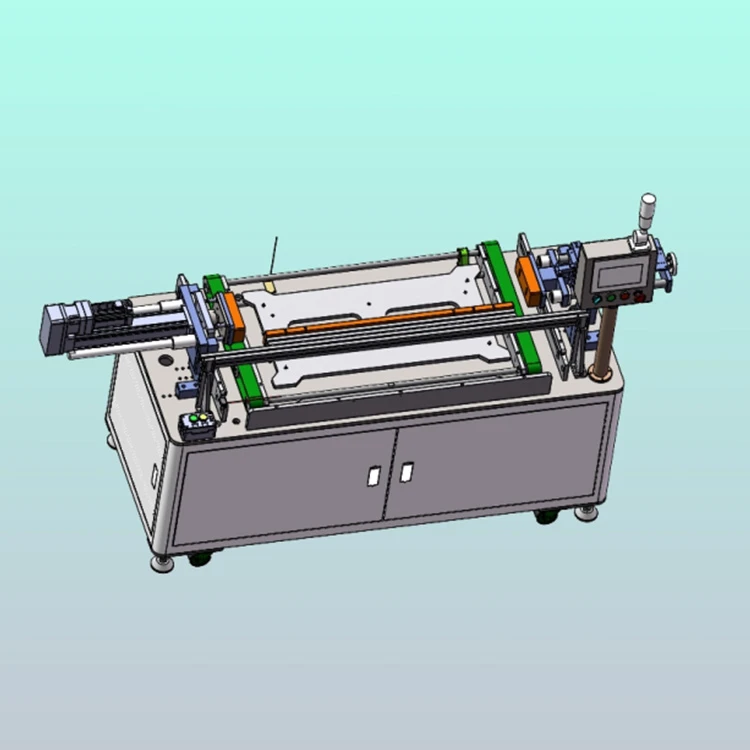

2. Stack the extruder Function overview: stack the cells on the OK channel of the sorting machine manually.After stacking, the stack extruder zes the cell module. After extrusion, artificial sleeve steel belt or plastic steel strip. After completion, it is transported to the double speed chain through the belt conveying line. |

3.CCD polarity detection machine Function overview: the module tooling plate enters the detection range through the double speed chain, the sensor senses the cylinder block, the jacking mechanism rises, the CCD automatically starts to detect the polarity direction of each battery, automatically recognizes the positive and negative of the battery polarity, addresses and outputs OK or NG signal. After the detection, the top rises down to the double speed chain, preventing the cylinder from falling.The module tooling continues to flow to the next station. |

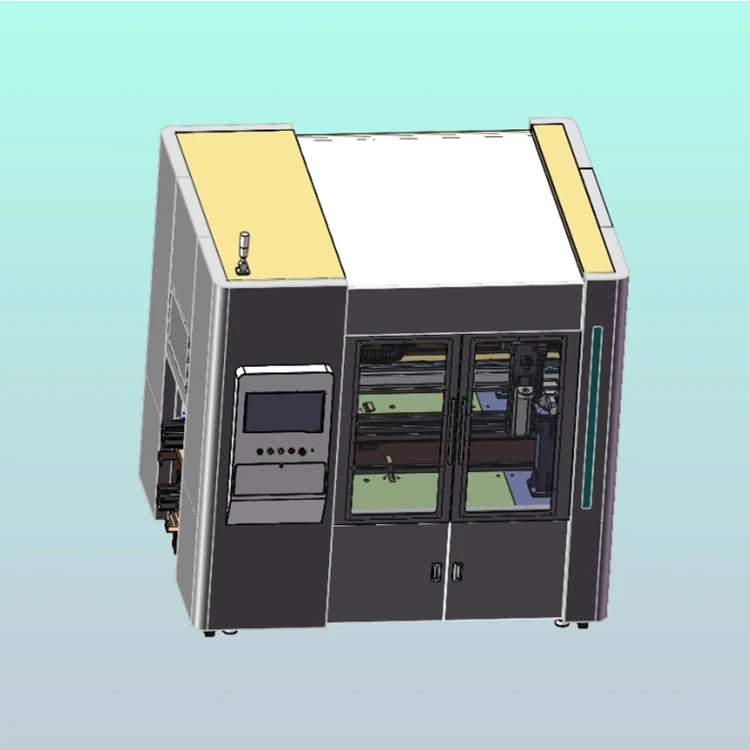

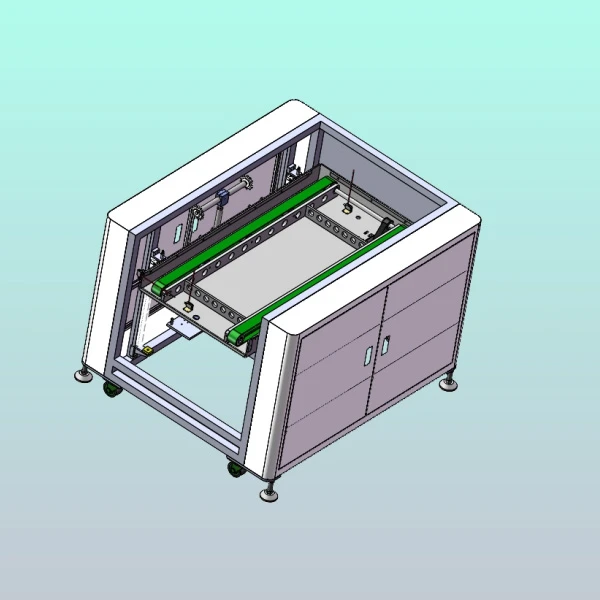

4. 200w laser cleaning machine Function overview: the module tooling plate enters the cleaning range through the double speed chain, the sensor induces the blocking cylinder block, the jacking mechanism rises up, the laser cleaning machine begins to identify the cell electrode column through vision, and after the visual upload position information, the laser cleans the surface of the pole column through the moving position of the gantry module. After cleaning, the top goes up to the speed chain, preventing the cylinder from falling. The module tooling panel continues to flow to the next station. |

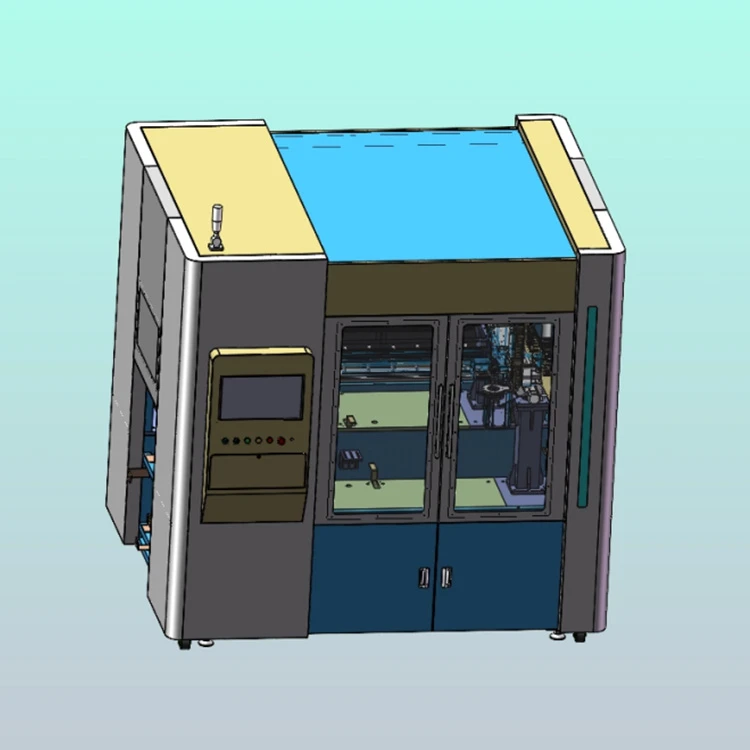

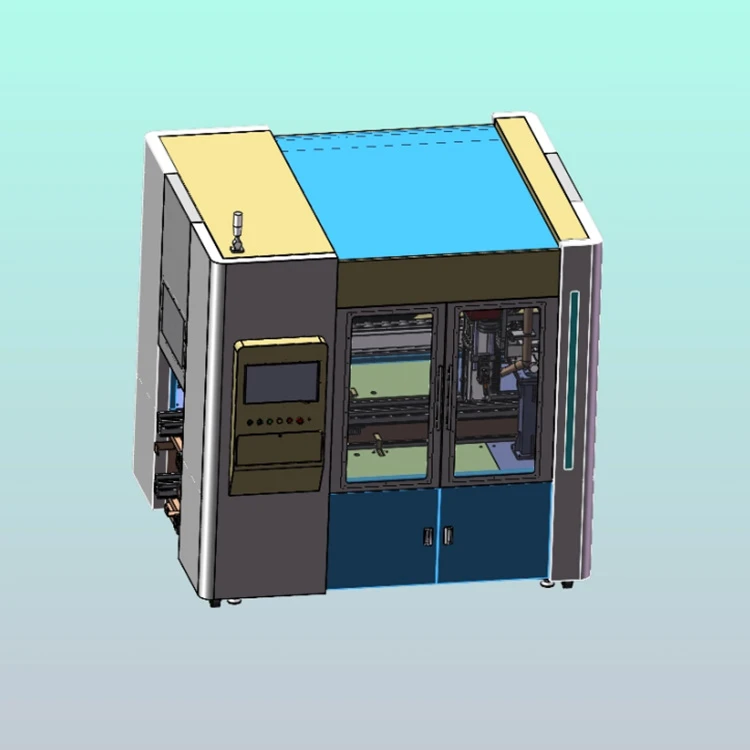

5. 6000w laser welding machine

Function overview: the module tooling plate enters the welding range through the double speed chain, the sensor induces the blocking cylinder block, the jacking mechanism rises up, the laser welding machine begins to identify the cell electrode column through vision, address the position information, and then laser welding through the moving position of the gantry module. After welding, the top rises and drops to the double speed chain, preventing the cylinder from falling. The module tooling panel continues to flow to the next station. |

6.Lift the machine Function overview: the tooling board rises or drops to the double speed chain through the lift.

|